In the intricate world of bespoke jewelry, the allure of creating a unique piece often overshadows the meticulous scrutiny a custom contract demands. Clients embark on this journey filled with dreams and sentimental visions, yet many overlook the dense legal language that could potentially turn their dream into a costly misadventure. The process, while artistic and personal, is fundamentally a significant financial transaction and a complex manufacturing agreement. Without a clear, detailed, and protective contract, customers leave themselves vulnerable to a range of issues, from minor disappointments to substantial financial loss.

One of the most critical and, unfortunately, common areas where disputes arise is the specification and potential substitution of the center stone. The contract must act as an unassailable blueprint for this most important component. Vague terms like "high quality" or "eye-clean" are subjective and practically meaningless without strict benchmarks. The agreement needs to explicitly state the exact type of gemstone (e.g., Natural Mozambican Ruby), and its precise characteristics: carat weight, precise measurements in millimeters, cut grade, color grade (using a recognized scale like GIA's D-to-Z for diamonds), and clarity grade with a plot mapping inclusions. Most importantly, it must include a clause strictly forbidding any substitution without the client's written and informed consent. Some vendors include broad language that allows them to replace the agreed-upon stone with one they deem "of equal or greater value," a term ripe for interpretation and abuse. The contract should guarantee that the stone delivered is the very one selected and documented in the initial certificate, which should be from a reputable, independent lab like GIA, AGS, or GRS for colored stones.

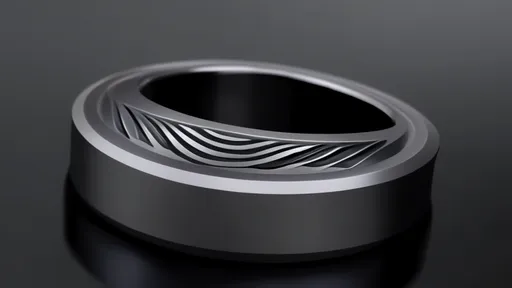

Beyond the glittering centerpiece lies the metalwork, a domain where weight and purity directly correlate to cost and integrity. Here, the trap is often one of subtle omission and allowable variance. A contract might simply state "18k yellow gold setting" without specifying the weight. This allows the manufacturer to use the absolute minimum amount of metal required to structurally hold the stones, potentially resulting in a flimsy, lightweight piece that feels inexpensive and may not endure daily wear. Astute clients will insist on a stipulated minimum metal weight, often expressed in grams. Furthermore, the contract must address the inevitable reality of metal loss during fabrication. A fair contract will specify a reasonable overage charge (e.g., 10-15%) to account for the metal lost during casting and finishing, but it should also include a provision for a refund if the actual metal used is less than the amount the client paid for. This two-way street ensures fairness and transparency.

The peril of ambiguity extends to the very design the client believes they have approved. A simple sketch or a verbal description is insufficient and leaves room for significant deviation. The final contract must incorporate an exact and detailed technical drawing or CAD rendering, specifying every dimension, prong type, gallery style, and milgrain detail. This drawing, signed by both parties, becomes the definitive reference point for the finished piece. It should also specify the exact number, size, and quality of melee (small accent stones). Are they natural or lab-grown? What is their color and clarity range? Often, these stones are overlooked, but they contribute significantly to the overall sparkle and value of the jewelry. Their poor quality or haphazard setting can drastically diminish the piece's beauty.

A comprehensive contract also dictates the timeline and the very process of approval. It should clearly state the manufacturing schedule with specific milestones and a firm final delivery date, including consequences for delays. Crucially, it must outline a formal inspection and approval process upon completion, before the client makes the final payment. This clause should grant the client the right to have the piece independently appraised and inspected by a gemologist of their choosing to verify it matches all the contractual specifications. If it does not, the contract must specify the remedies: whether it's remaking the piece, a significant price adjustment, or a full refund. Without this right to independent verification, the client is solely relying on the vendor's word.

Finally, the often-overlooked boilerplate clauses at the end of the document hold immense power. Jurisdiction clauses dictate where you can file a lawsuit if something goes wrong. Warranty clauses should be explicit about what is covered (e.g., manufacturing defects, stone loosening) and, just as importantly, what is not (e.g., loss of stones due to accidental damage, wear and tear). It should specify the warranty duration and the process for repair. A clause regarding the ownership of the design is vital; you want to ensure that the custom design you paid for is yours alone and won't be replicated and sold to others.

Navigating a custom jewelry contract requires a shift from an emotional mindset to a analytical one. It is not a document to be skimmed but a essential tool for risk mitigation. The most successful and satisfying custom jewelry experiences are built on a foundation of clear communication, meticulous documentation, and a contract that protects the dreams—and the investment—of the client. By insisting on precise language, definitive specifications, and fair clauses, you ensure that the only surprise when you open that final box is one of sheer delight.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025