The textile industry has long been chasing the elusive dream of spinning ultra-fine cashmere fibers, pushing the boundaries of what was once considered physically impossible. For decades, the 0.08mm diameter mark stood as an unbreakable barrier – until now. A groundbreaking development in nano-spinning technology has shattered this limitation, opening doors to a new era of luxury fabrics with unprecedented softness and thermal properties.

The 0.08mm Barrier: Why It Mattered

Cashmere's value has always been tied to fiber fineness. Traditional wisdom held that 0.08mm represented the absolute lower limit for spinnable cashmere fibers – any thinner and the fibers would lack sufficient structural integrity for processing. This limitation forced manufacturers to balance between fineness and practicality, often sacrificing one for the other. The finest cashmere garments still contained fibers hovering near this threshold, leaving textile scientists wondering if nature's design could be improved upon.

What few anticipated was how dramatically nanotechnology could rewrite these rules. By reengineering the fundamental approach to fiber formation rather than simply refining existing methods, researchers have achieved what mechanical processing alone never could. The implications extend far beyond creating softer sweaters – this breakthrough challenges our basic understanding of natural fiber manipulation.

Nano-Spinning's Secret: Molecular Alignment

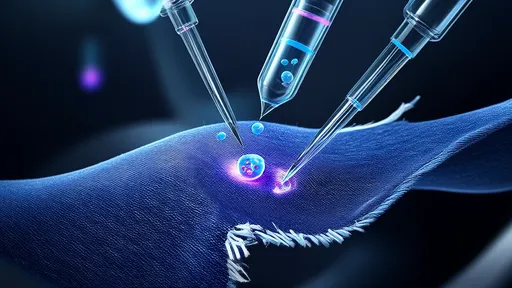

The key innovation lies in controlling fiber formation at the molecular level. Conventional spinning stretches pre-formed fibers thinner, while the new technique builds fibers from carefully aligned protein chains. Using electromagnetic fields to orient cashmere keratin molecules during extrusion, scientists can now create continuous filaments measuring as fine as 0.02mm – four times thinner than the previous "unbreakable" limit.

This molecular precision achieves two seemingly contradictory goals simultaneously: extreme fineness without sacrificing strength. The aligned molecular structure compensates for reduced fiber diameter by eliminating weak points that normally develop during mechanical processing. Early testing shows the nano-spun fibers actually surpass conventional cashmere in tensile strength while weighing significantly less.

From Laboratory to Luxury

Translating this technology from lab experiments to commercial production presented formidable challenges. Scaling up the precise electromagnetic controls required completely rethinking textile manufacturing infrastructure. The solution emerged through hybrid systems combining traditional spinning machinery with nanotechnology modules – an approach preserving existing industry investments while enabling quantum leaps in product quality.

Pilot production runs have yielded astonishing results. Fabric samples demonstrate heat retention properties 30% superior to conventional cashmere at identical weights, with a hand feel described by testers as "liquid warmth." The enhanced surface area from ultra-fine fibers creates unique light interaction effects, giving the material an almost luminous quality under certain lighting conditions.

Environmental Implications

Perhaps the most unexpected benefit comes in sustainability. Producing warmer fabrics from less raw material could significantly reduce the environmental impact of cashmere production. Preliminary estimates suggest the technology might enable 40% reductions in goat herds needed to meet global cashmere demand, potentially easing grassland degradation in sensitive regions like Mongolia and Inner China.

The water savings prove equally impressive. Nano-spinning requires no chemical treatments to achieve fiber separation, eliminating one of traditional cashmere processing's most polluting steps. Early adopters are already marketing the technology as "dry processing" cashmere – a potentially transformative claim for eco-conscious luxury consumers.

The New Luxury Landscape

As the first nano-spun cashmere products reach premium retailers, pricing strategies reveal how manufacturers view this innovation. Rather than positioning it as a mass-market alternative, brands are introducing the technology at price points 50-70% above conventional premium cashmere. This reflects both current production costs and a deliberate strategy to maintain exclusivity while scaling up capacity.

The aesthetic possibilities are expanding as quickly as the technical ones. Designers report that the new fibers accept dyes with unprecedented clarity and uniformity, enabling color effects previously impossible with natural fibers. Some experimental weaves combine nano-spun and conventional cashmere in single garments to create texture gradients that feel different across a single piece of clothing.

Challenges Ahead

Not all industry observers are convinced this revolution will proceed smoothly. Traditional cashmere producers express concerns about protecting geographical indications and quality standards. There are active debates about whether nano-spun cashmere should qualify as "natural fiber" under various labeling regulations – a decision with significant marketing and tariff implications.

Consumer acceptance also remains an open question. While early adopters enthusiastically embrace the technological story, some heritage luxury buyers remain skeptical of anything perceived as "engineered" cashmere. Marketing teams are carefully balancing innovation narratives with reassurances about preserving cashmere's essential character.

Beyond Cashmere: Wider Applications

The implications extend far beyond cashmere production. Researchers are already adapting the technology to other challenging natural fibers like qiviut (musk ox wool) and guanaco. There's even promising work applying similar principles to plant-based fibers, potentially revolutionizing materials like extra-fine cotton and linen.

Medical applications are particularly intriguing. The biocompatibility of nano-aligned keratin fibers shows promise for advanced wound dressings and even nerve regeneration scaffolds. Textile engineers collaborate with biomedical researchers to explore these cross-disciplinary possibilities, suggesting the 0.08mm breakthrough might represent just the first of many boundaries to fall.

As the industry digests these developments, one thing becomes clear: the rules of luxury textiles are being rewritten. What began as an effort to spin slightly finer cashmere has uncovered entirely new approaches to working with natural fibers. The 0.08mm barrier now stands as a reminder of how technological leaps can transform even the most established industries.

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025

By /Aug 13, 2025